- Your cart is empty

- Continue Shopping

- Home /

- Page

Tech Info

Punch Diameter: This is the size of the punch tip, which is the hole diameter. Order the round punch by inputting the diameter in inches, for example, .3125.

Punch Dimensions: These are the measurements of the shaped punch tip. The punch dimensions are the size of the shaped hole. Order the shaped punch by inputting the dimensions in inches, for example, .2500 and .5000.

Die Diameter: To calculate the Die Diameter, use this formula:

Punch Diameter + Die Clearance = Die diameter

For example, if you are punching a .250” hole in 1/4″ mild steel, the die clearance is .050”. The calculation would be .250” Punch Diameter + .050” Die Clearance = .300” Die Diameter. Order the round die by inputting .300 as the Die Diameter.

Die Dimensions: To calculate the Die Dimensions, use this formula:

Punch Dimensions + Die Clearance = Die Dimensions

For example, if you are punching a .1250” x .6250” shaped hole in 1/4″ mild steel, the die clearance is .050”. The calculation would be .1250” x .6250” Punch Dimensions + .050” Die Clearance = .175” x .675” Die Dimensions. Order the shaped die by inputting .175 and .675 as the Die Dimensions.

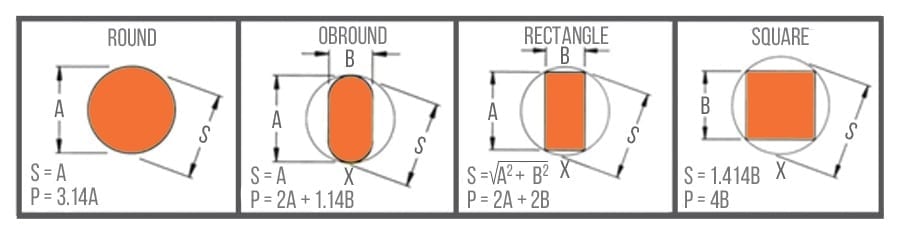

Common Shape Dimensions

When ordering shaped punches and dies, specify dimensions as required below: